Tips for Correctly Store Hot Stamping Foil Rolls

Hot stamping foil is a valuable material used in various industries for adding decorative and metallic finishes to products. To ensure the longevity and quality of hot stamping foil, proper storage is crucial. Here we will list some essential guidelines for storing hot stamping foil to maximize its shelf life.

Find a cool, dry, and clean storage area for your hot stamping foil. High temperatures and humidity can negatively impact the foil's adhesive properties and overall quality.

Avoid areas with direct sunlight or extreme temperature fluctuations, as they can cause the foil to deteriorate faster.

Keep the storage area at a stable temperature between 15°C and 25°C to prevent the foil from warping or becoming brittle.

Maintain a humidity level of around 40% to 50% to prevent moisture absorption, which can affect the foil's performance.

If your storage area is prone to excessive dust, consider covering the foil or using protective sleeves to prevent dust accumulation, which can affect the foil's adhesive performance.

In environments with high pollution or airborne contaminants, consider using additional protective measures such as air filters or enclosing the foil in sealed cabinets.

Hot stamping foil should be stored in its original packaging whenever possible. The packaging is designed to protect the foil from external factors and maintain its quality.

If the original packaging is damaged or not available, use an airtight and moisture-resistant container to store the foil. Ensure the container is clean and free from any contaminants.

If you have multiple types or colors of hot stamping foil, it is essential to organize them properly. This will make it easier to identify and use the desired foil, minimizing the time spent searching and handling.

Additionally, when using hot stamping foil, it is good practice to use the oldest stock first to prevent wastage and ensure freshness.

Hot stamping foil is sensitive to chemical substances and solvents. Keep the foil away from areas where these materials are stored or used.

Chemical exposure can compromise the foil's adhesive properties and lead to discoloration or degradation. Store the foil separately from any potentially harmful substances.

Avoid storing hot stamping foil near heat sources such as heaters, ovens, or machinery that emit heat. High temperatures can cause the foil to warp, melt, or lose its adhesive properties.

Excessive handling can cause creases, scratches, or other physical damage to the foil. Minimize unnecessary handling to maintain the foil's integrity.

When handling the foil, ensure your hands are clean and dry. Oils, dirt, or moisture on your hands can transfer onto the foil, affecting its adhesion and overall appearance.

Educate your employees about the importance of proper hot stamping foil storage and provide them with clear guidelines on how to handle and store the foil correctly.

Regularly reinforce these practices to ensure everyone in your organization understands the significance of proper storage techniques.

Periodically check the stored hot stamping foil for any signs of deterioration, such as discoloration, adhesive damage, or moisture presence. Remove and discard any damaged or compromised foil.

Implement a stock rotation system to use the oldest foil first and prevent the expiration of unused stock.

Choose a Suitable Storage Area

Find a cool, dry, and clean storage area for your hot stamping foil. High temperatures and humidity can negatively impact the foil's adhesive properties and overall quality.

Avoid areas with direct sunlight or extreme temperature fluctuations, as they can cause the foil to deteriorate faster.

Maintain Consistent Temperature and Humidity

Keep the storage area at a stable temperature between 15°C and 25°C to prevent the foil from warping or becoming brittle.

Maintain a humidity level of around 40% to 50% to prevent moisture absorption, which can affect the foil's performance.

Consider Other Environmental Factors

If your storage area is prone to excessive dust, consider covering the foil or using protective sleeves to prevent dust accumulation, which can affect the foil's adhesive performance.

In environments with high pollution or airborne contaminants, consider using additional protective measures such as air filters or enclosing the foil in sealed cabinets.

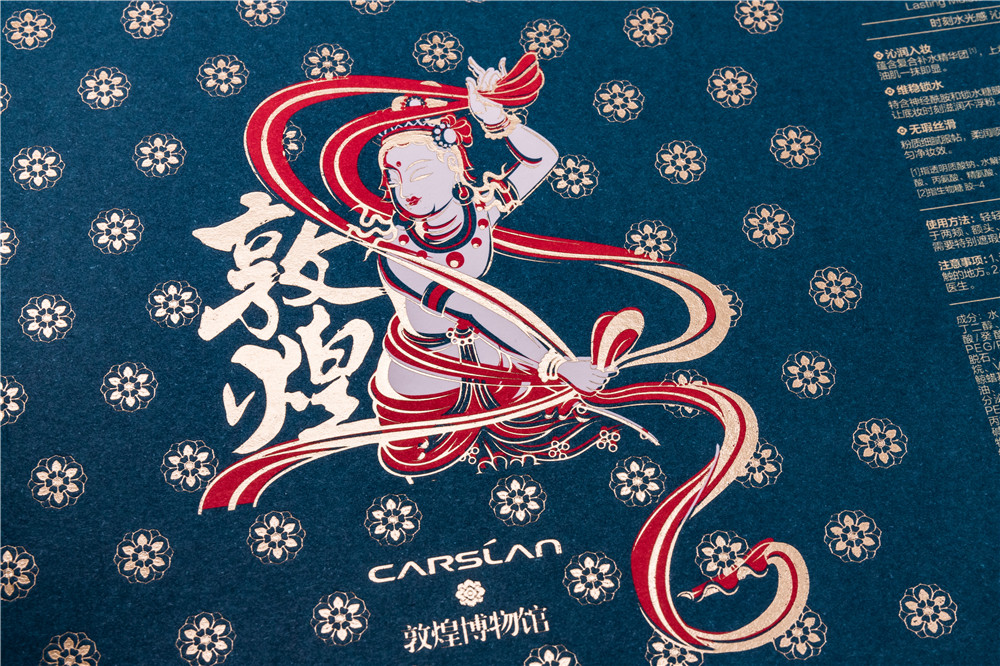

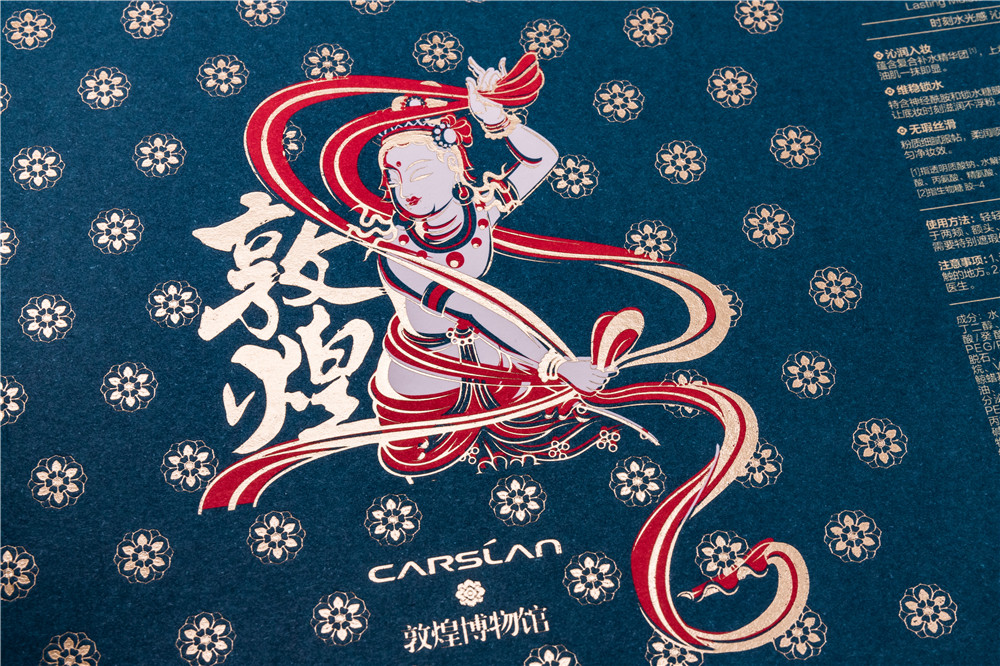

Use Protective Packaging

Hot stamping foil should be stored in its original packaging whenever possible. The packaging is designed to protect the foil from external factors and maintain its quality.

If the original packaging is damaged or not available, use an airtight and moisture-resistant container to store the foil. Ensure the container is clean and free from any contaminants.

Organize by Type and Age

If you have multiple types or colors of hot stamping foil, it is essential to organize them properly. This will make it easier to identify and use the desired foil, minimizing the time spent searching and handling.

Additionally, when using hot stamping foil, it is good practice to use the oldest stock first to prevent wastage and ensure freshness.

Avoid Exposure to Chemicals and Solvents

Hot stamping foil is sensitive to chemical substances and solvents. Keep the foil away from areas where these materials are stored or used.

Chemical exposure can compromise the foil's adhesive properties and lead to discoloration or degradation. Store the foil separately from any potentially harmful substances.

Keep Away from Heat Sources

Avoid storing hot stamping foil near heat sources such as heaters, ovens, or machinery that emit heat. High temperatures can cause the foil to warp, melt, or lose its adhesive properties.

Minimize Handling

Excessive handling can cause creases, scratches, or other physical damage to the foil. Minimize unnecessary handling to maintain the foil's integrity.

When handling the foil, ensure your hands are clean and dry. Oils, dirt, or moisture on your hands can transfer onto the foil, affecting its adhesion and overall appearance.

Train Employees on Proper Storage

Educate your employees about the importance of proper hot stamping foil storage and provide them with clear guidelines on how to handle and store the foil correctly.

Regularly reinforce these practices to ensure everyone in your organization understands the significance of proper storage techniques.

Regularly Inspect and Rotate Stock

Periodically check the stored hot stamping foil for any signs of deterioration, such as discoloration, adhesive damage, or moisture presence. Remove and discard any damaged or compromised foil.

Implement a stock rotation system to use the oldest foil first and prevent the expiration of unused stock.