Advantages of Using Cold Foil in Printing

In the ever-evolving world of printing technology, innovations continue to pave the way for enhanced visual appeal and improved consumer engagement.

One such breakthrough that has changed the printing industry is cold foil printing. This article explores the captivating advantages of using cold foil in printing, and its impact on packaging, and answers some frequently asked questions.

Cold foil printing is a state-of-the-art printing technique that involves transferring a metallic foil to the substrate without the need for heat. The process is accomplished using an adhesive, UV-curable inks, and UV light to cure the ink, resulting in a stunning metallic effect on the printed material.

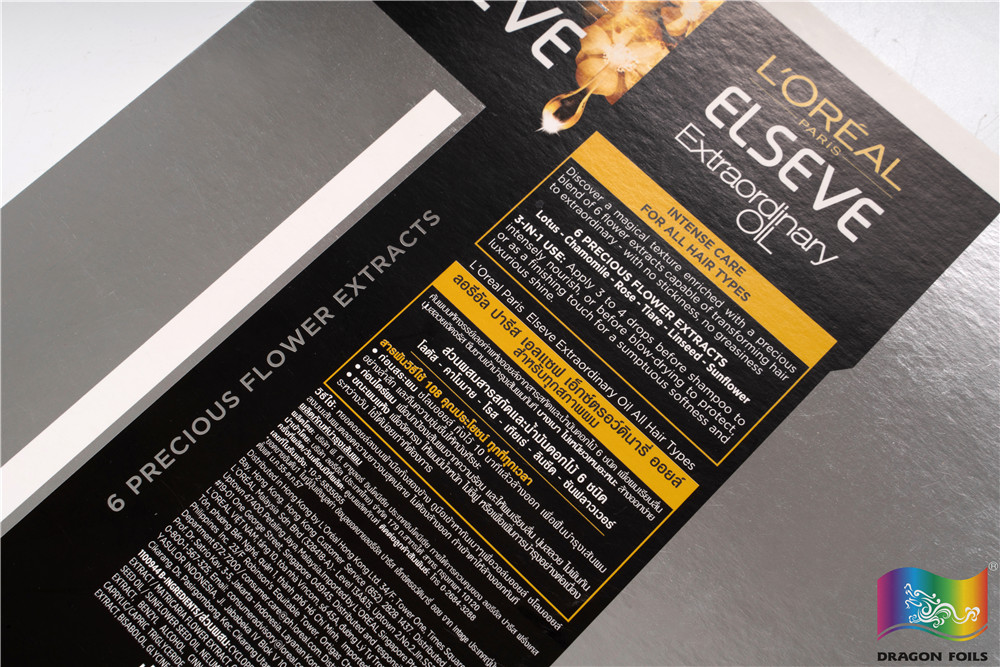

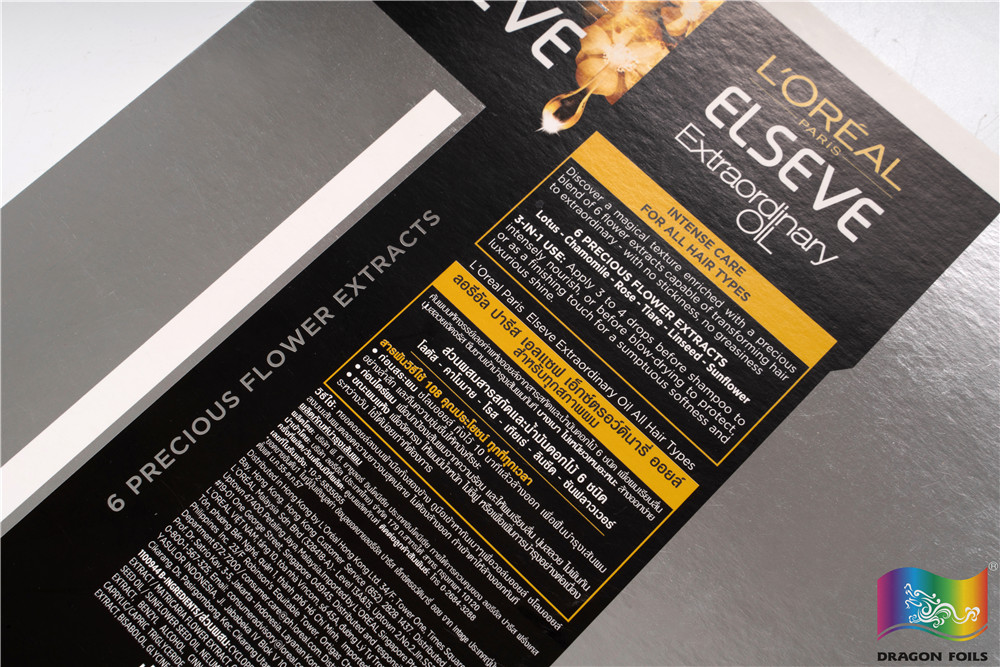

● Exceptional Aesthetics: Cold foil printing delivers unrivaled visual appeal and a luxurious finish. The metallic foils lend an eye-catching shimmer and brilliance to the artwork, elevating the overall appearance of the packaging.

● Cost-Effective Solution: Compared to traditional hot foil stamping, cold foil printing is more cost-effective, making it an attractive choice for both small-scale and large-scale printing projects. Its efficiency in ink usage also contributes to cost savings.

● Versatility and Flexibility: Cold foil printing allows for intricate designs and fine detailing, enabling designers to bring their creative visions to life. It can be used on various substrates, such as paper, cardboard, and even certain plastics, expanding its applications across multiple industries.

● Environmentally Friendly: Cold foil printing is an eco-friendly option as it generates less waste and consumes lower energy during the printing process. Additionally, the absence of heat eliminates the emission of harmful VOCs (Volatile Organic Compounds), making it a sustainable choice for environmentally conscious businesses.

● Faster Turnaround Time: The absence of heat in cold foil printing results in quicker production cycles compared to traditional hot foil stamping. This accelerated process allows businesses to meet tight deadlines and launch their products faster in the market.

A1: Yes, cold foil printing is compatible with various inks, including UV-curable inks and certain water-based inks, ensuring excellent adhesion to the substrate and vibrant color reproduction.

A2: Absolutely! Cold foil printing is safe for food packaging as it meets industry standards for direct food contact. The process utilizes FDA-approved foils and inks, ensuring consumer safety.

A3: Yes, cold foil printing can achieve holographic effects by using specially designed holographic foils. These foils create a mesmerizing play of light, adding an extra dimension of allure to the packaging.

A4: The metallic effect achieved through cold foil printing is highly durable and resistant to abrasion. This ensures that the packaging maintains its brilliance and appeal throughout its shelf life.

A5: Absolutely! Cold foil printing is exceptionally well-suited for short-run projects, making it an ideal choice for limited-edition packaging and promotional materials.

In conclusion, cold foil printing stands tall as a cutting-edge technology that provides a multitude of advantages over traditional printing methods. Its exceptional aesthetics, cost-effectiveness, versatility, and eco-friendliness make it a preferred choice for businesses aiming to enhance their packaging's visual appeal. Embrace the brilliance of cold foil printing and elevate your packaging to new heights in the competitive market.

One such breakthrough that has changed the printing industry is cold foil printing. This article explores the captivating advantages of using cold foil in printing, and its impact on packaging, and answers some frequently asked questions.

Cold Foil Printing

Cold foil printing is a state-of-the-art printing technique that involves transferring a metallic foil to the substrate without the need for heat. The process is accomplished using an adhesive, UV-curable inks, and UV light to cure the ink, resulting in a stunning metallic effect on the printed material.

Advantages of Cold Foil Printing

● Exceptional Aesthetics: Cold foil printing delivers unrivaled visual appeal and a luxurious finish. The metallic foils lend an eye-catching shimmer and brilliance to the artwork, elevating the overall appearance of the packaging.

● Cost-Effective Solution: Compared to traditional hot foil stamping, cold foil printing is more cost-effective, making it an attractive choice for both small-scale and large-scale printing projects. Its efficiency in ink usage also contributes to cost savings.

● Versatility and Flexibility: Cold foil printing allows for intricate designs and fine detailing, enabling designers to bring their creative visions to life. It can be used on various substrates, such as paper, cardboard, and even certain plastics, expanding its applications across multiple industries.

● Environmentally Friendly: Cold foil printing is an eco-friendly option as it generates less waste and consumes lower energy during the printing process. Additionally, the absence of heat eliminates the emission of harmful VOCs (Volatile Organic Compounds), making it a sustainable choice for environmentally conscious businesses.

● Faster Turnaround Time: The absence of heat in cold foil printing results in quicker production cycles compared to traditional hot foil stamping. This accelerated process allows businesses to meet tight deadlines and launch their products faster in the market.

Frequently Asked Questions about Cold Foil Printing

Q1: Can cold foil printing be used with different types of inks?

A1: Yes, cold foil printing is compatible with various inks, including UV-curable inks and certain water-based inks, ensuring excellent adhesion to the substrate and vibrant color reproduction.

Q2: Is cold foil printing suitable for food packaging?

A2: Absolutely! Cold foil printing is safe for food packaging as it meets industry standards for direct food contact. The process utilizes FDA-approved foils and inks, ensuring consumer safety.

Q3: Can cold foil printing achieve holographic effects?

A3: Yes, cold foil printing can achieve holographic effects by using specially designed holographic foils. These foils create a mesmerizing play of light, adding an extra dimension of allure to the packaging.

Q4: How durable is the metallic effect in cold foil printing?

A4: The metallic effect achieved through cold foil printing is highly durable and resistant to abrasion. This ensures that the packaging maintains its brilliance and appeal throughout its shelf life.

Q5: Is cold foil printing suitable for short-run projects?

A5: Absolutely! Cold foil printing is exceptionally well-suited for short-run projects, making it an ideal choice for limited-edition packaging and promotional materials.

Conclusion

In conclusion, cold foil printing stands tall as a cutting-edge technology that provides a multitude of advantages over traditional printing methods. Its exceptional aesthetics, cost-effectiveness, versatility, and eco-friendliness make it a preferred choice for businesses aiming to enhance their packaging's visual appeal. Embrace the brilliance of cold foil printing and elevate your packaging to new heights in the competitive market.